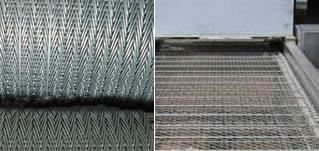

T304 Stainless Steel Balanced Weave Wire Mesh Belt

Shuke manufactures and exports T304 S.S.Balanced Weave Wire Mesh Belt designed with special spirals. Connected with stainless steel cross rod. This mesh belt is a type of balanced weave conveying belt made with stainless steel mesh and rod. The open mesh structure allows quick draining and free air circulation. This flat surface stainless steel belt is ideal for food and pharmaceutical drying uses.

Technical Information of Balanced Weave Wire Mesh Belt with Special Spirals

The woven wire mesh:

Balanced weave 3.1X3.6X1.25X0.9;

Edge type: welded;

Woven wire mesh with special spiral at 50.8MM centers for Ø3.66MM S/S cross rods;

Belt overall width: 1210MM maximum (+0/-2MM), length 18 meters.

Mesh and rod materials: stainless steel T304.

The Chain and Its Connecting to the Rods:

Chain centers: 1191 norminal

C2042 connecting links every 48 pitches facing inwards;

Side chains C2042 on both sides fitted to cross rods.

Cross rods replace chain pins. Cross rod ends to be welded to washers on outside of chain links. Welds are to be heliarc or equivalent. Welds to be large and sound. Cross rods must be free to rotate. There is to be no clearance between belt mesh and side chains.

Chain Material: carbon steel.

Features of the Balanced Weave 304 Mesh Conveyor Belt:

1) The Open mesh design is suitable for quick drainage and free air circulation.

2) The belt has a smooth and flat conveying surface.

3) The stainless steel mesh and rod surface is easily cleaned.

4) Easy replacement of damaged or worn sections.

5) Endless splicing.

6) Economical compared with other types of metal conveyor belts.

7) High strength.

Application:

The belt is widely used in solar-power, mine, metallurgy, petroleum, chemical, food, pharmeceuticals,

glass, printing and machine making industries, also used in heat treatment, drying, cooling, and various material handling, steaming, filtering, sludge draining, printing, etc.